At HUBER+SUHNER, we’ve established a deep expertise and close collaboration with our customers in the Test and Measurement industry and a critical understanding of their coax-to-PCB needs. Our all-new MXPD70 [...]

yukaihl

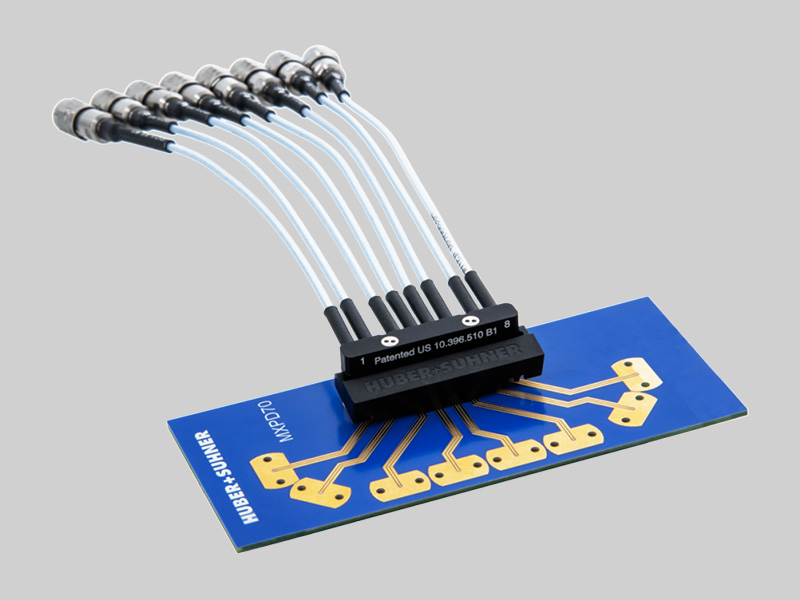

At HUBER+SUHNER, we’ve established a deep expertise and close collaboration with our customers in the Test and Measurement industry and a critical understanding of their coax-to-PCB needs. Our all-new MXPD70 multicoax test solution is just the next development step in a comprehensive portfolio of proprietary products to address these needs.

MXPD or “Multicoax Precision Direct” is a miniaturized, solderless multicoax test solution that supports two critical trends in the semiconductor industry:

Many companies face increased internal budget pressures, and our connector-less MXPD solution helps by eliminating the need for expensive connectors and saving vital time in the operational soldering processing.

Another trend is the use of heaters and/or coolers mounted directly above the DUTs, creating height restrictions for multicoax cables. To address this, our MXPD70 cable assemblies are available in both straight and right-angle configurations, providing sufficient clearance for these heating/cooling devices.

With frequency of up to 70 GHz, these assemblies will make a significant difference for our customers’ High Speed Digital Testing (HSDT) requirements, for test and characterization boards, within automated test equipment and for specific customer applications as well.

Features and benefits of MXPD70 multicoax solutions

- Solderless compression mount interface: No PCB solder-down components required

- Superior signal integrity up to 70 GHz: Ready for 112 Gbps data analysis

- Pitch 3.4 mm/0.134 inch center-to-center: Dense footprint get assemblies closer to the DUT

- 1×8 straight and 1×8 right angle versions available (with super-low profile of 11.9 mm/0.469 inch): Tailored for mounting beneath heaters/coolers with restricted clearance

- Identical layout for both straight and right angle version: Reduced simulation efforts and more convenient assembly replacements when necessary

- No hard gold plating required on PCB: An advantageous design of spring-loaded center pin/ground contacts

- Swivel-mounted interface protection: Integrated interface protection for assembly not in use